WHO ARE WE?

The NIWMET- Steel Construction company has been present inon the market since 1999.

CONSTRUCTIONS

Specjalizujemy się głównie w usługach ślusarsko-spawalniczych oraz szeroko rozumianej obróbce metalu. Zajmujemy się produkcją małych i średnich konstrukcji stalowych.

PRODUCTION

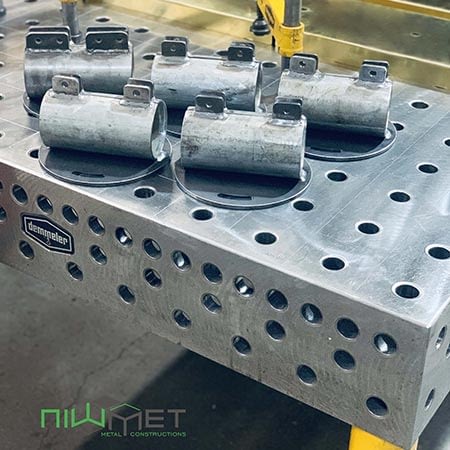

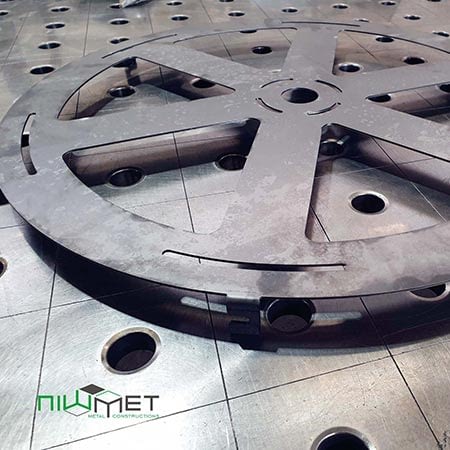

In our constatntly expanding machine park we have modern CNC machines, thanks to which we’re able to precisly and quickly produce details of various complexity levels.

QUALITY

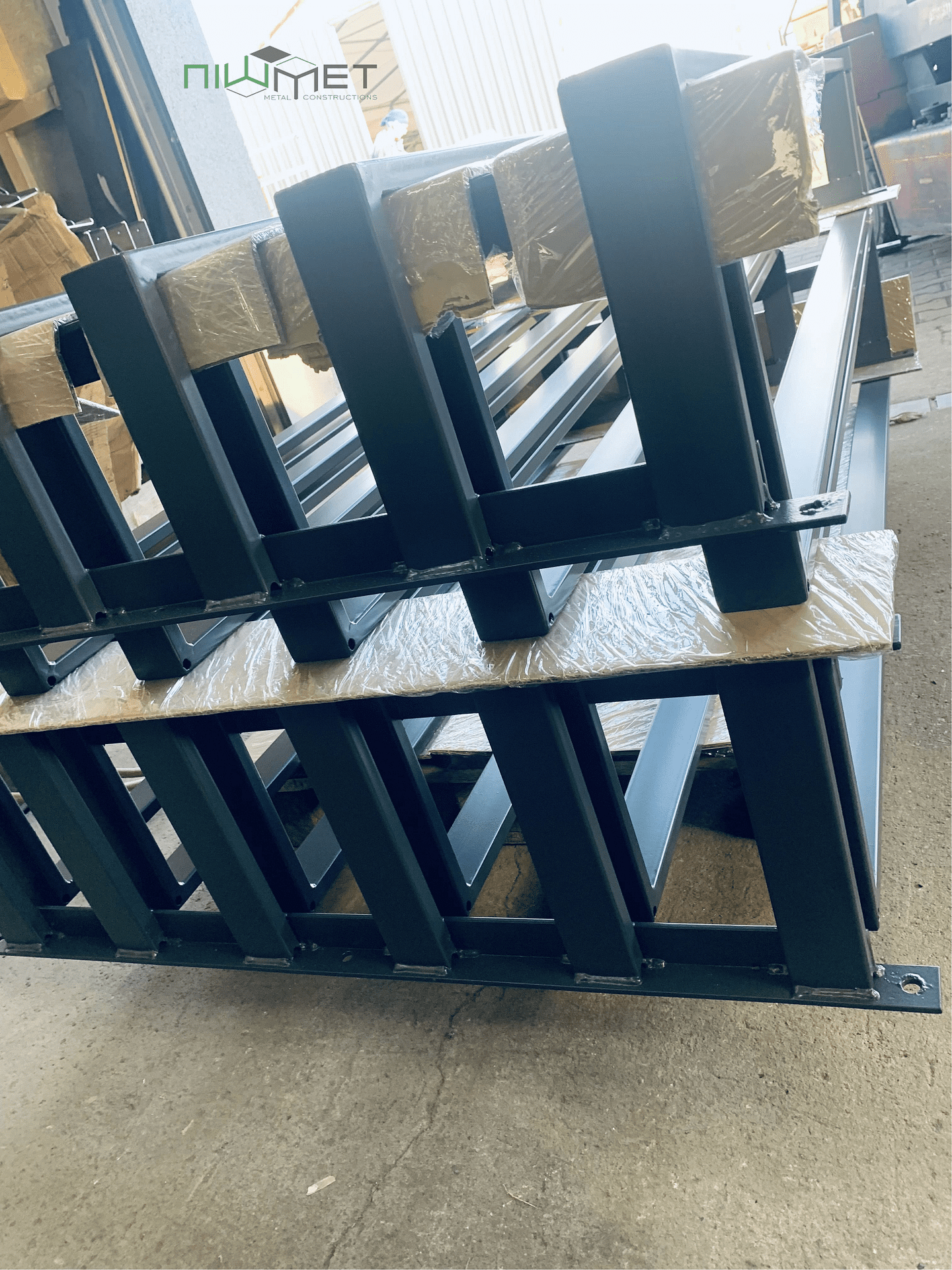

Since our company’s inception we’ve made every effort to ensure that each of the elements produced by us is of high quality and details in the entire series are perfectly reproduced.

We mainly deal with serial production.

We strive to make each investment a joint success between the investor and our company.

We warmly invite your cooperation.

OUR OFFER

We cordially invite you to explore our offers and look forward to future cooperation.

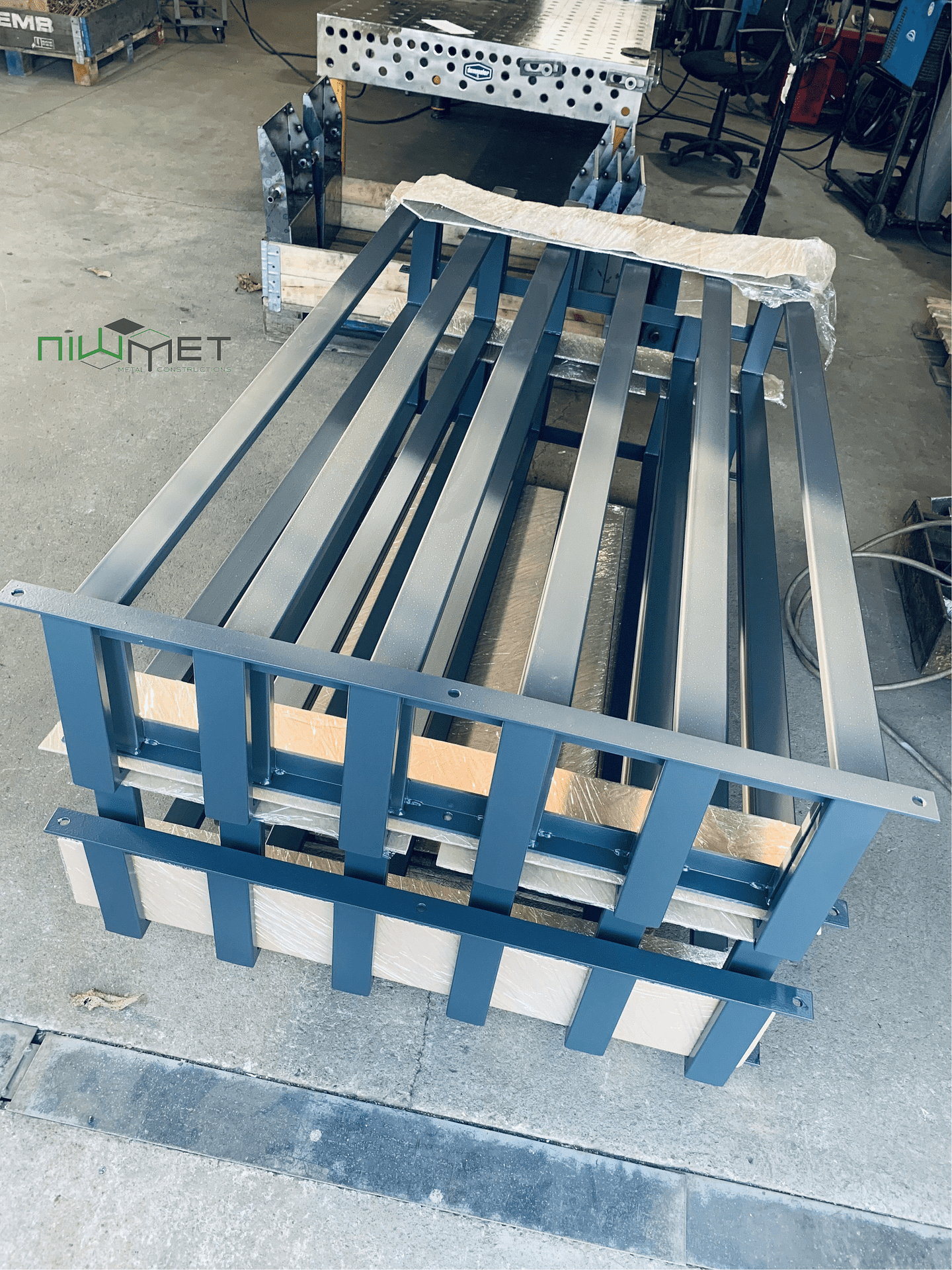

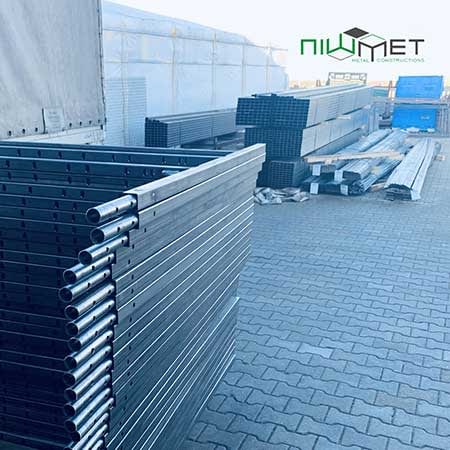

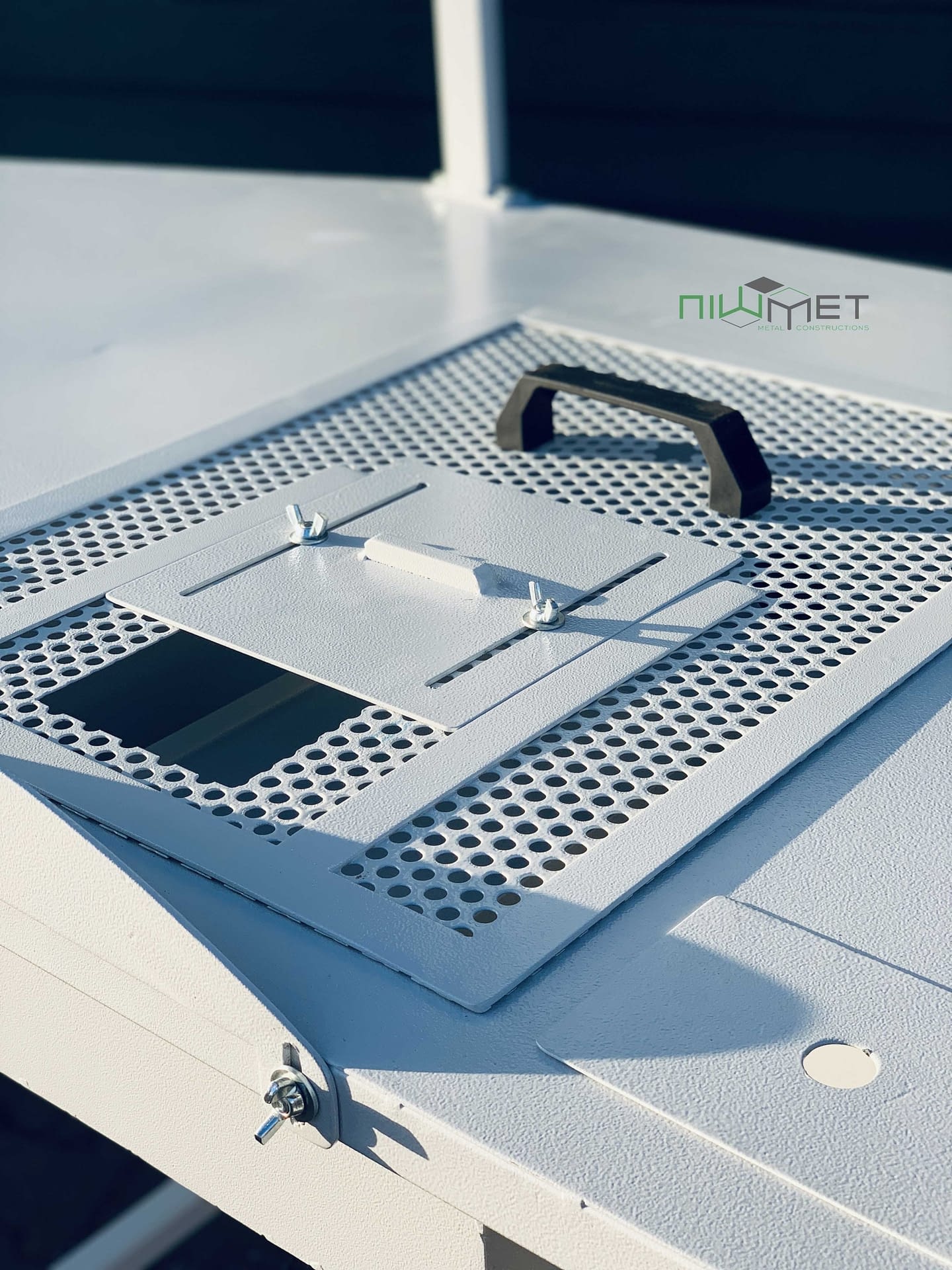

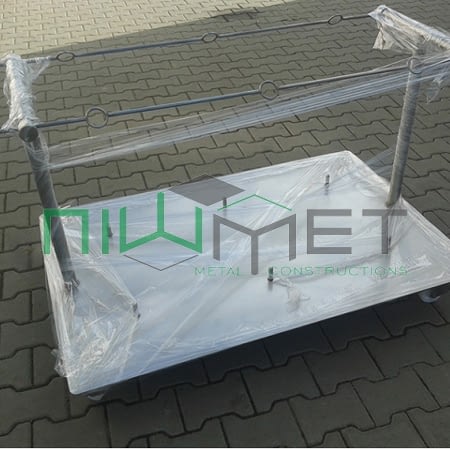

STEEL STRUCTURES

Our company has many years of experience in the production of various types of steel structures, solutions for industry and more. In recent years we have completed many projects in the country as well as in the European Union.The main service our company offers is the production of various types of steel structures and the production of metal elements welded using the TIG and MIG-MAG methods. We also provide aluminium,brass and stainless steel welding services. We manufacture steel structures such as: industrial pallets, baskets, platforms, stands, stillages, frames for furniture, trusses,tanks,railings, fenders etc.

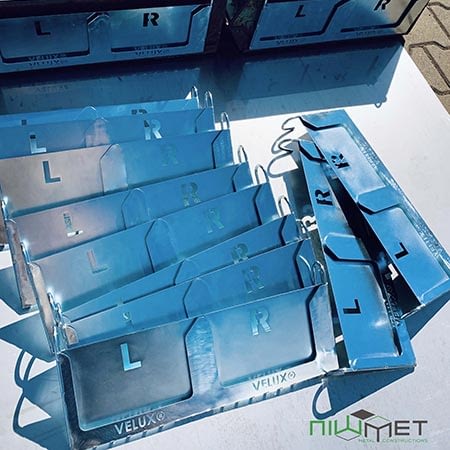

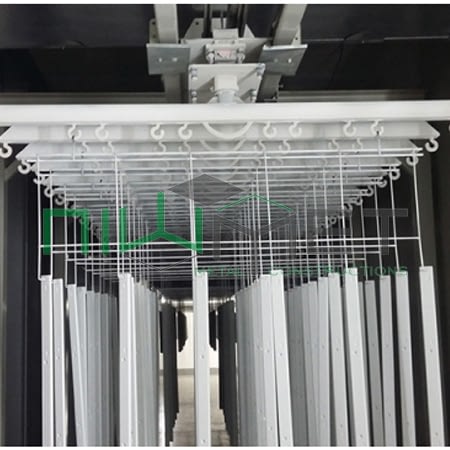

CNC 3D WIRE BENDING

We offer wire bending,shaping and forming services in CNC 3D and 2D technology.Our company guarantees high quality and repetability due to the speed of manufacturing the components.We bend the wires on a modern numerically controlled bending machnie,equipped with an automatic ADR Q1000 wire coil unwinder.This machine is able to produce details from wire with a diameter of 2-6mm both in two and three dimensions.Our work is characterized by perfect reproduction of all pieces of product delivered to the customer.

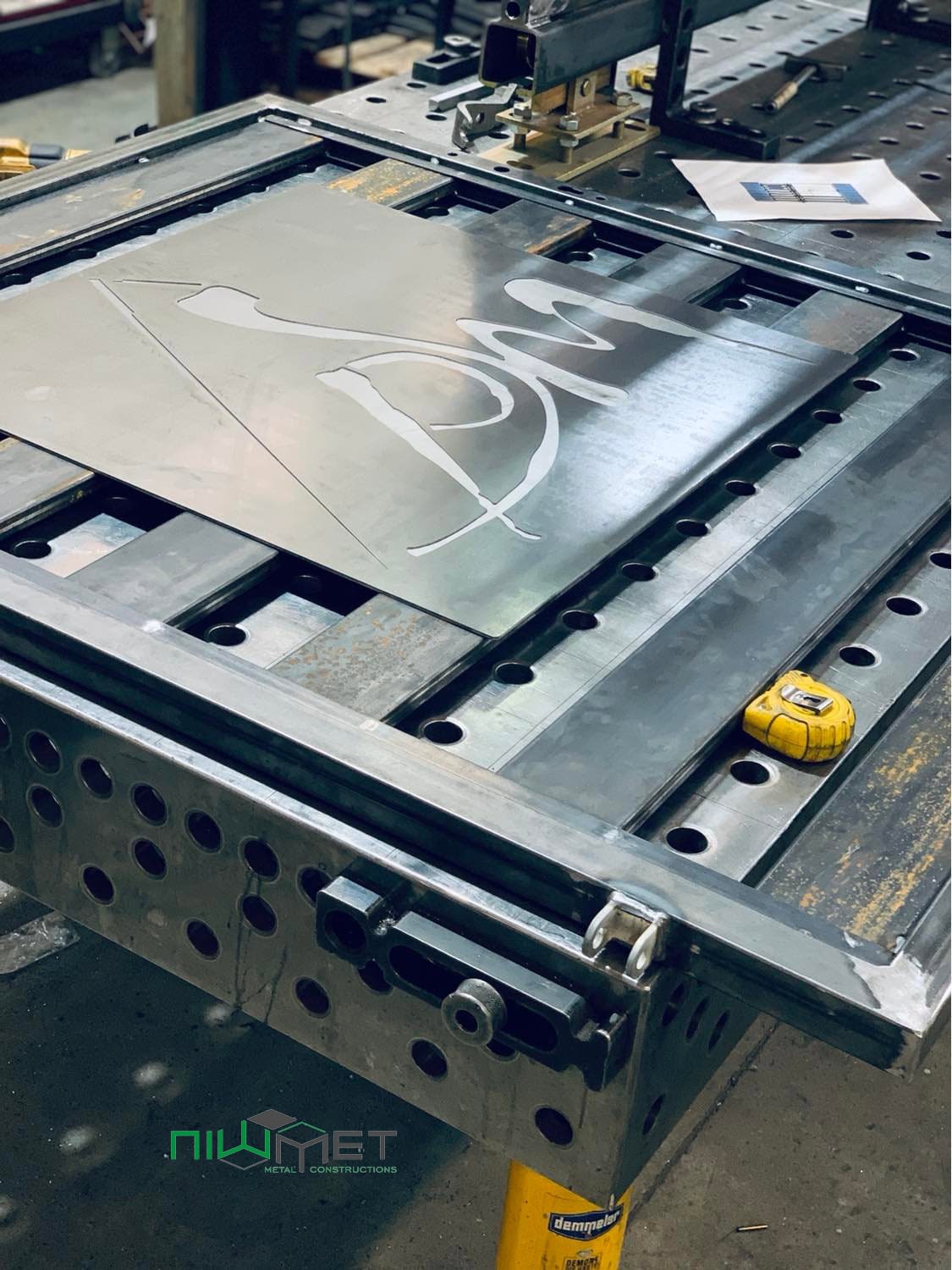

CNC PLASMA CUTTING

We offer plasma cutting services, currently the most flexible method of cutting steel elements. Plasma cutting is performed using a special arc, which allows precise work without the risk of damaging the treated element.We cooperate with leading Polish manufacturers of steel products and always offer our customers the right quality at the right price. We’re able to provide you with consistent supplies and competetive prices.

BANDSAW CUTTING

Bearing in mind the needs of our customers we’ve extended our offer to include complex cutting services of products purchased from us. We try to systematically enlarge our Machine Park with professional equipment that guarantees efficient and precise processing of matallurgical products and steel constructions.It’s ideal for cutting various types of profiles, angles, pipes, etc. We’re using a fully automated band saw with large size capabilities. Band saw cutting is characterized by rapidity, high precision and importantly, dimensional accuracy.

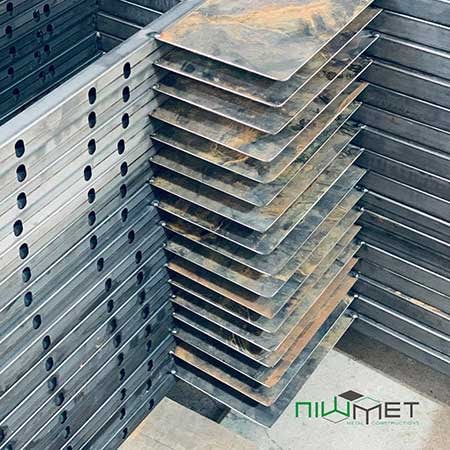

CNC SHEET METAL BENDING (PRESS BRAKE)

CNC bending is one of the main metal forming technologies. We use a computer-controlled CNC press brake which guarantees the precision and repeatability of an angle by using the laser measurement of the bending angle it’s equipped with. CNC machnining allows for fast, precise and highly repeatable production of complex shapes. This technology is particularly advantageous if the repeatability of the entire process is assumed, the aim is to obtain a large series of identical elements at a low cost per unit. It’s perfect for both thin and thick sheets.

CNC LASER CUTTING

Laser cutting is one of the most precise and repeatable systems for thermal cutting of metal sheets. By using a laser it is possible to cut even the most complex shapes which are limited only by the size of the sheet. The resulting components require virtually no further processing. Thanks to this type of CNC equipment the surfaces remain smooth, are not subject to deformation and guarantee 100% repeatability of details.

CNC-TURNING (MANUAL)

Our products can include precision turned products. CNC turning is one of the machining techniques.These machnies are equipped with a lathe knife that by performing a linear motion processes a rotating worpiece. This process allows for numerical control of a given machine making it possible to manufacture elements taking into account even the smallest details. The lathe can be programmed to perform specific motions, aimed at producing a final product with a specific shape and dimensions.

CNC MILLING

Milling is a cutting process in which a cutter is used to remove the surface of a material by moving in a given direction at an angle. CNC milling machines are either computer controlled or manually controlled. Computer programming allows the machine to make the required cuts but manual controls allow the CNC machine operator to slow down, speed up or otherwise adjust the process as necessary.

SANDBLASTING

It’s a technological process of cleaning or shaping any surface with an abrasive material in a stream of compressed air or possibly liquid. The effect of sandblasting is similar to sanding but the cleaned surface is more even and gets the roughness required for painting, additionaly there are no problems with cleaning hard-to-reach corners or curves.

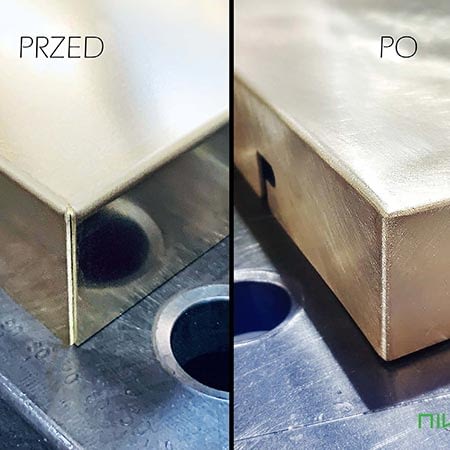

DEBURRING

We offer a deburring service for metal elements. Deburring the edges allows for the final finishing of the product and giving it the appropriate shape. This improves the appearance and functionality of the material. It prevents its destruction, increases the safety of use of the future consumer, but also translates into the operation and durability of machines using processed details. Deburring is essential for the automotive, furniture, machinery, medical and optical industries.

We adapt our offer to the individual needs of our clients.

Possibility of serial production. Attractive prices, high quality, 100% satisfaction.Short delivery times.

We have our own transport at our disposal. This allows us to deliver your order to its destination.

We look forward to your inquiries and responding with all our offers.

OUR IMPLEMENTS

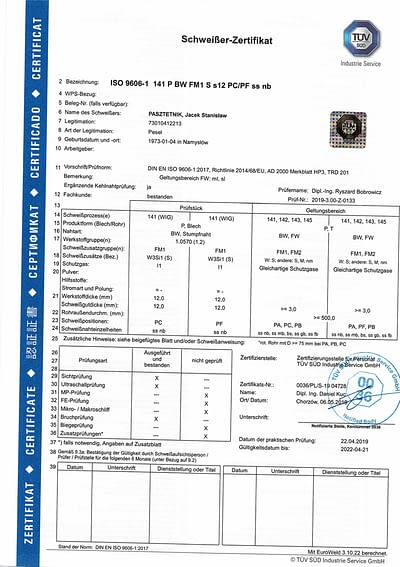

CERTIFICATES

NIWMET Pasztetnik Jacek Company confirm that all constructions delivered meet all quality requirements set by Polish and EU law.

We received welding quality certificates on the 16/06/2019 and 21/06/2019.

Quality supervision at the plant is carried out by a qualified person based on procedures of the Factory Production Control system.

Contact

FILL OUT FORM

FIND US